Laser cutting technology has revolutionized numerous industries by giving precision and efficiency that classic methods battle to match. For anyone who is thinking about diving into the world of laser cutting, It is important to know how laser slicing machines work and why They are getting to be indispensable. Let's break down anything from the fundamentals on the advanced options of such equipment and examine why they could be the proper in shape for your requirements.

On the core of the know-how may be the laser cutter, a device that uses a centered laser beam to chop or engrave materials. As opposed to other chopping strategies, a laser cutter directs a superior-driven laser beam via a lens, which concentrates the light into a great level. This allows for unbelievably precise cuts and intricate designs on an array of elements. Visualize using a laser to carve out in depth styles with a piece of metallic—it's that kind of precision which makes laser cutters jump out.

The 2-Minute Rule for Sheet Metal Laser Cutter

Industrial laser reducing usually takes this concept to a bigger scale, wherever superior-powered lasers are used in manufacturing environments to cut by thicker resources with amazing precision. For industries for instance automotive, aerospace, and construction, exactly where tolerances are limited and materials are difficult, industrial laser chopping is often a recreation-changer. These devices can deal with massive sheets of metal along with other supplies with small waste and most precision.

Industrial laser reducing usually takes this concept to a bigger scale, wherever superior-powered lasers are used in manufacturing environments to cut by thicker resources with amazing precision. For industries for instance automotive, aerospace, and construction, exactly where tolerances are limited and materials are difficult, industrial laser chopping is often a recreation-changer. These devices can deal with massive sheets of metal along with other supplies with small waste and most precision.CNC laser slicing is an additional fascinating advancement in this area. CNC means Computer system Numerical Management, and it refers back to the automatic control of equipment instruments employing pcs. By integrating CNC technological know-how with laser reducing, you receive a machine that not merely cuts but does so by using a amount of consistency and repeatability that handbook approaches are unable to match. This is particularly helpful for tasks demanding a number of similar elements or advanced designs.

Laser cutting technological innovation is continuously evolving, with new improvements bettering performance, pace, and versatility. For instance, fashionable laser cutting devices typically contains State-of-the-art program which allows For additional intricate types and more rapidly processing times. With these advancements, It really is less complicated than ever to accomplish substantial-good quality cuts and types, no matter whether you are engaged on little prototypes or significant-scale manufacturing operates.

In terms of precision laser slicing, the ability to obtain specific measurements and intricate details is unmatched. That is crucial for industries the place every millimeter counts, including in electronics or great jewellery. Laser cutters can tackle really great particulars, producing them ideal for apps where by precision is paramount. If you have ever marveled within the good specifics of the enjoy or maybe the fragile options of the circuit board, chances are high a laser cutter was linked to its generation.

Sheet metallic laser cutters are a certain form of laser chopping equipment meant to tackle flat sheets of metallic. These devices are perfect for chopping pieces for equipment, automotive elements, together with other metal merchandise. The precision and speed of sheet metallic laser cutters permit brands to generate higher-quality sections effectively, cutting down production time and prices.

The Greatest Guide To Sheet Metal Laser Cutter

Laser cutting expert services have also become greatly out there, presenting enterprises entry to substantial-top quality chopping with no have to have for in-dwelling machines. Lots of service get the details vendors offer a range of options, from simple cuts to elaborate models, and can do the job with different elements, like metals, plastics, and composites. What this means is you may obtain best-notch laser chopping technology with no the significant financial investment in machinery.

Laser cutting expert services have also become greatly out there, presenting enterprises entry to substantial-top quality chopping with no have to have for in-dwelling machines. Lots of service get the details vendors offer a range of options, from simple cuts to elaborate models, and can do the job with different elements, like metals, plastics, and composites. What this means is you may obtain best-notch laser chopping technology with no the significant financial investment in machinery.Not known Facts About Laser Cutting Technology

Among the crucial benefits of laser cutting methods is their versatility. They're able to Lower by a variety of materials, which include metals, plastics, Wooden, and in many cases fabrics. This makes them incredibly beneficial in a number of industries, from manner style to production. No matter whether you're looking to create personalized areas for a product or layout intricate styles for your bit of art, laser cutting methods can manage all of it.Concerning operational performance, laser cutting machines certainly are a info here best alternative. They typically call for considerably less handbook intervention in comparison with other slicing methods, resulting in less errors and decrease labor expenses. This automation also contributes to consistent top quality throughout manufacturing operates, which is very important for maintaining benchmarks in industrial configurations.

Laser cutting engineering is not just about cutting components; It is also about the opportunity to engrave or mark surfaces with precision. This is especially helpful for developing in depth labels, serial figures, or ornamental designs. Using a laser cutter, you can realize significant-good quality engravings that happen to be both strong and aesthetically pleasing, which makes it a useful tool for both practical and decorative applications.

The adaptability of laser cutting know-how signifies that it isn't really restricted to unique industries. From developing tailor made signage to crafting intricate jewelry, the purposes are large and diversified. This flexibility is probably the explanation why laser cutting happens to be such a favorite choice throughout distinctive fields.

A different benefit of laser chopping is its power to generate sophisticated styles and styles without the will need For added tooling. Conventional chopping techniques usually call for precise resources for different designs, but by using a laser cutter, you can certainly alter the design and make changes to the fly. This capability is especially beneficial for prototyping and custom made function, wherever flexibility is vital.

Laser chopping techniques also are known for their cleanse cuts and minimal content squander. The precision from the laser beam signifies that cuts will often be incredibly slender, minimizing the level of excess materials that should be trimmed absent. This efficiency not merely can help in reducing fees and also contributes to extra sustainable manufacturing methods by reducing squander.

For enterprises seeking to put money into laser slicing devices, it is vital to consider the particular demands of your respective functions. Things including the types of supplies you'll be reducing, the complexity of the types, and the amount of labor will all affect the kind of laser cutter that best fits your demands. Undertaking extensive investigation and consulting with authorities may help you make an informed final decision.

The way forward for laser slicing know-how appears to be like promising, with ongoing enhancements driving enhancements in pace, accuracy, and versatility. As technological know-how proceeds to evolve, we could assume a lot more progressive options and applications to arise, generating laser reducing an even more integral section of producing and design and style.

Unknown Facts About Industrial Laser Cutting

In summary, laser cutting equipment and programs supply unparalleled precision, efficiency, and flexibility. Regardless of whether you're involved with industrial manufacturing, tailor made layout, or any get started area that needs correct chopping or engraving, laser reducing technology has a thing to offer. By being familiar with the assorted components of laser reducing, from machines to companies, you are able to superior value its impression and possible for your individual tasks.

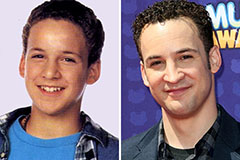

Ben Savage Then & Now!

Ben Savage Then & Now! Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!